WASTE WATER TREATMENT PLANT

MOVING BED BIOFILM REACTOR (MBBR)

We know that 75% of the world’s fresh water resources are contaminated, the remaining is fast disappearing. Soon how well we Survive will depend on how well we conserve water. Thankfully technology has advanced enough to offer us choices in water conservation. One of the most reliable way to do today is by recycling water. We at Global Aqua Teck offer you various reliable method to recycle the water through our superior waste water treatment plants.

MBBR technology employs thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual biocarrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high density population of bacteria that achieves high rate biodegradation within the system, while also offering process reliability and ease of operation. Process has continuous inflow to the bioreactor and intermittent cleaning, using influent wastewater, which removes excess (sludge) from the biofilm carriers.

Process Benefits

- Energy Saving and Cost Effective

- Compact Design –Requires less Space than traditional waste water systems

- Flexible to upgrade an existing ASP/SBR or MBBR to provide additional capacity

- Single Pass Process-No return activated sludge stream required

- Load Responsive –Actively sloughed biofilm automatically responds to load fluctuations

- Reliable /Simple Operation/ Reuse of Treated water / Superb Effluent

- Quality/Minimal Maintenance

Mbbr processes are an excellent solution for wastewater applications including:

BOD Reduction/Nitrification/Total Nitrogen removal

Sewage . Marine industry, Laundry facilities, Pulp and paper industry, Breweries, Food and Beverage processing industry, Textile industry, Tanneries, etc

Moving Bed Biofilm reactor systems deliver a flexible, cost-effective, and easy-to-operate means to address current wastewater requirements and the expandability to meet future loads or more stringent discharge requirements within a compact design.

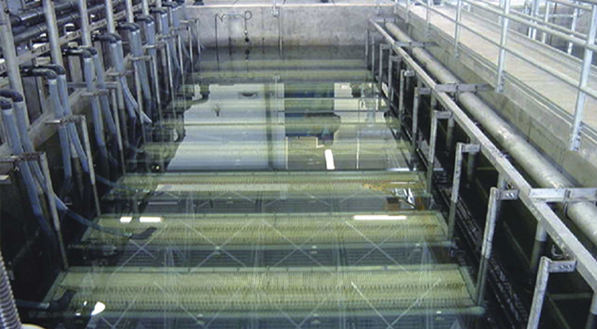

MEMBRANE BIO REACTORS

Membrane Bioreactors have opened a gamut of opportunities in waste water treatment. The solid liquid separation that is conventionally carried out in gravity based clarifier is replaced by membrane filtration in a MBR System, thus combining the strength of biological treatment process and efficiency of membrane filtration. This and several other advantages have made the MBR system ideally suited for treatment of strong industrial waste water, Domestic waste water and reclamation of water

Process Benefits

The performance of solid –liquid separation efficiency is improved due to higher efficiency of membrane over conventional

The Sensitiveness of the separation process to the internal and external factors can be reduces thereby improving the reliability of the system.

Control on several process related factors can be improved like sludge retention time (SRT) or men cell residence time, organic loading , waste sludge volume and characteristics etc that can improve the efficiency of the biochemical reaction process

Removal of nutrients and refractory (Biodegradation – Resistant) Substances can be improved.

Complete removal of microorganisms and pathogens from effluent is possible that reduces the disinfection requirement.

Less operation control during steady state condition as well as rapid initial process start up can be achieved.

The foot print of a traditional waste water treatment plant can be reduced by replacing large (Clarifier) tanks with MBR modules.